Overview

The Oeko-Tex standard is the voluntary certification standard possibly evaluating the potential harmful property of a textile product. It was introduced by the public’s demand on the textile product unharmful to the human body in the beginning of 1990s.

The ÖsterreichTextilInstitut (ÖTI) and the Hohenstain Research Institute of Germany developed the Oeko-Tex standard on the basis of the existing test standard. Before Oeko-Tex was generated, there had been no product label enabling a consumer to know about the physical effect of a textile or no unified safety standard enabling the textile industry to actually evaluate the potential harmful ingredient of a textile.

Oeko-TexType

| Logo |

Details |

|---|

|

- Attaching the certification seal to the textile type going through the test on harmful substances from the raw materials to the finished goods

- The independent and internationally unified test and certification system for the raw textile materials, intermediate product, and finished product of all processing stages and the used accessory materials

|

|

- The certification system meaning sustainable textile and leather production and being used for the production facility of the textile and leather industries

- It should go through the 6 certifications of chemical substance control, environment performance, environment management, social responsibility, quality control, and worker’s health protection and safety during the textile and leather production and finishing processes and finally implement the environment-friendly production process and working condition and the best health and safety.

|

|

- It shows the textile and leather products going through the test for harmful substances and certifies that the manufacturer performed manufacturing in the sustainable and socially responsible condition.

|

|

- The certification customized for the leather product going through the test on harmful substances

- Certification for half-finished and finished leather products, a leather textile material, and a leather accessory

|

|

- The verification system of the textile and leather industries for implanting the Greenpeace DETOX Campaign standard within the production facility

- Checking to build the system for managing chemical substances and for monitoring wastewater quality instead of certification

|

|

- Identifying the environment-friendly one unharmful to health for the chemical substance, colorant, and adjuvant used in the textile and leather industries

|

Classes of Oeko-Tex Standard100

| Class |

Details |

Example |

|---|

| Ⅰ |

Products for babies |

Clothes, toys, bedding, towels, etc. |

| Ⅱ |

Products with direct contact to skin |

Underwear, bedding sheets, T-shirts, etc. |

| Ⅲ |

Products without direct contact to skin |

Jackets, coats, etc. |

| Ⅳ |

Decoration material |

curtains, tablecloth, sofa covers, mattresses, etc. |

Product Inspection Category

- Carcinogenic and allergic colorant

- The AZO colorant prohibited due to regulations

- Formaldehyde

- Chlorobenzene and chlorotoluene

- Heavy metal

- Phthalic acid in baby supplies

- Emission of volatile ingredients

- Bad odor

- Chlorophenol, etc.

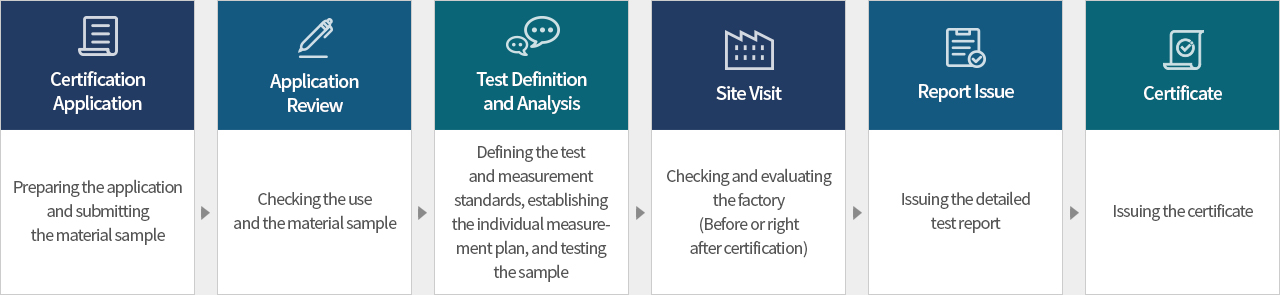

Procedure

Validity and Follow-Up

The effective period of the certificate is 1 year. The random test on the product should be done for renewal every year. The quality control audit is done every three years after the first year of certification. The re-test result should be satisfactory for certification renewal after certification acquisition. The manufacturer’s conformance declaration may be requested in some cases. The payment of the re-test and certification costs is requested for renewal. The same test report number is stated on the certificate after renewal.